LPR plate hotels deliver the sample from the storage space through the opening in top of the device surface straight onto the space above the instrument with periscope lift so it can fit under any liquid handler deck or workstation. The lift mechanism is located in the center of the turntable and can rotate around its own axis. As the common interface of the plate hotel and the robotic environment there may be several transfer stations located around the opening in the deck in a circular arrangement. Such arrangement concept reduces bottle necks in throughput by optimizing required robot travel and eliminates the need for special transfer stations, extra robotic arms or extended grippers. This leaves ample room for additional equipment and increases the capacity of the automated line.

Like in the LPX Line the LPR handling will accept most plate types without modification or adaptation. Simultaneous use of various plate types is possible.

All members of LPX line can be equipped with various types of packages, options and a wide selection of useful accessories. For details please refer to Packages, Options and Accessories section of the web page and relevant flyer.

Like in the LPX Line the LPR handling will accept most plate types without modification or adaptation. Simultaneous use of various plate types is possible.

All members of LPX line can be equipped with various types of packages, options and a wide selection of useful accessories. For details please refer to Packages, Options and Accessories section of the web page and relevant flyer.

LiCotel LPR44

LPR44 is the smallest member of the LPR Line. Its 44 MTP capacity make it perfectly suitable of small-scale integration, highly miniaturized applications. Its fast retrieval time makes it perfect for throughput issues. It is ideal for laboratories with room constrains.

Two stationary cassettes that can easily be removed are located between the lift mechanism. The transfer station is located opposite to the cassettes. In addition to the z-axis the lift mechanism has a rotation axis (turn movement) that turns the transport shovel facing one of the two cassettes or facing the transfer station. The stationary cassettes allow the periscope lift be the only moving part, reducing vibration and movement of the samples.

LPR44 is available as an open system on the platform and in protection cover.

Two stationary cassettes that can easily be removed are located between the lift mechanism. The transfer station is located opposite to the cassettes. In addition to the z-axis the lift mechanism has a rotation axis (turn movement) that turns the transport shovel facing one of the two cassettes or facing the transfer station. The stationary cassettes allow the periscope lift be the only moving part, reducing vibration and movement of the samples.

LPR44 is available as an open system on the platform and in protection cover.

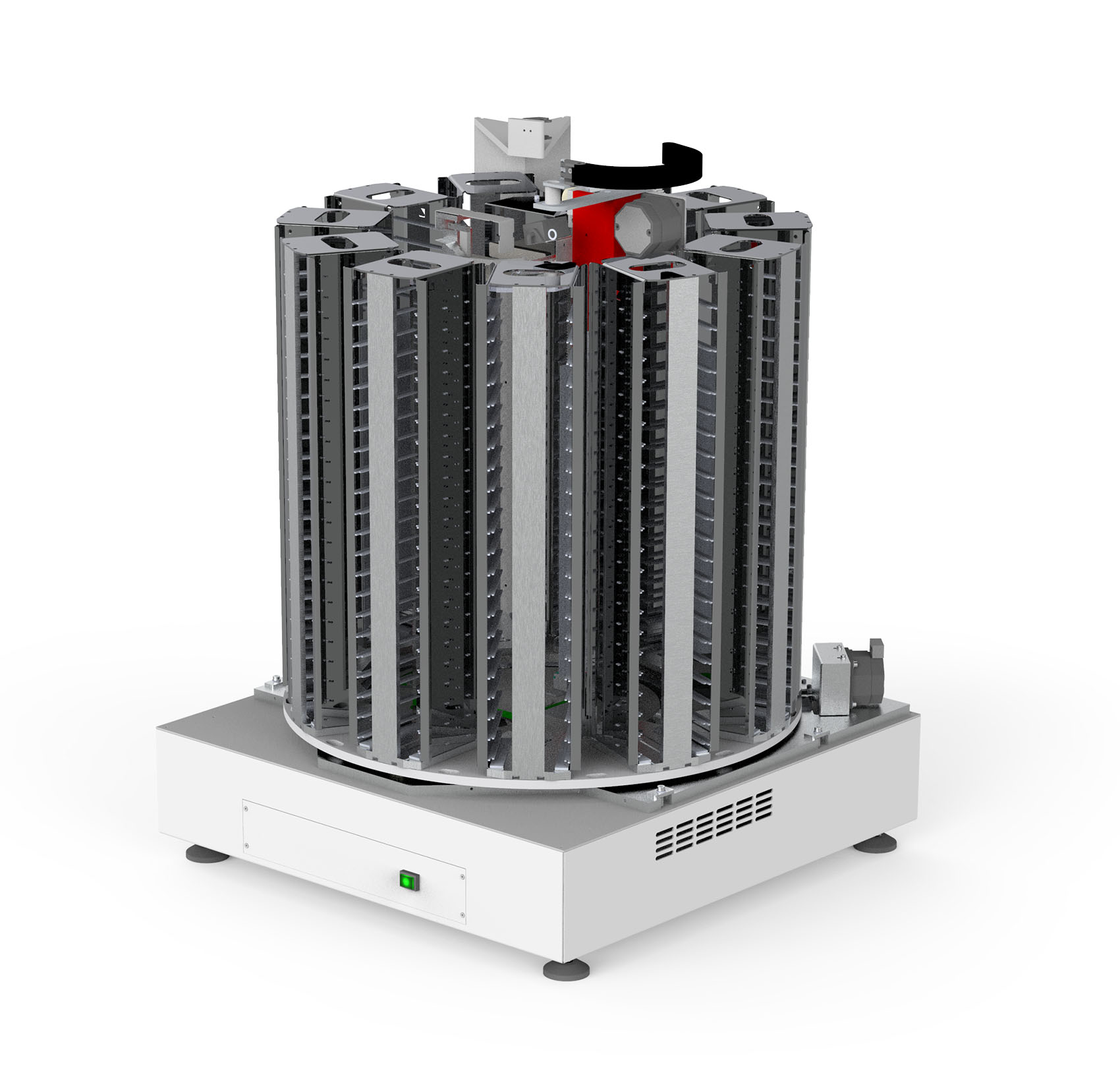

LiCotel LPR240

LPR240 will hold up to equivalent of 242 MTP with 23mm pitch. It is ideal for multiple cassette/sample configurations and large integrations. The unit sits entirely under the workstation or liquid handler deck. Multiple transfer station can be used to increase production and throughput.

The LPR240 is ideal for protein crystallization work because the carrousel can be stationary with the star concept allowing the periscope to be the only moving part reducing vibration of the samples. While allowing full remote access on handling there is still possibility to manually access the cassettes and samples from the front of the instrument.

For better access to cassettes located in the back of the instrument the carrousel maybe positioned automatically or be rotated manually. LPR240 is available as an open system on the platform and in complete housing.

The LPR240 is ideal for protein crystallization work because the carrousel can be stationary with the star concept allowing the periscope to be the only moving part reducing vibration of the samples. While allowing full remote access on handling there is still possibility to manually access the cassettes and samples from the front of the instrument.

For better access to cassettes located in the back of the instrument the carrousel maybe positioned automatically or be rotated manually. LPR240 is available as an open system on the platform and in complete housing.