Exclusive use of components that meet industrial standards guarantee ultra-long-term reliability and stability even under harsh conditions.

- Capacities – from 44 to over 3 000 MTP equivalent

- Compact – smallest footprints in the industry

- Flexible – bench-top, stand-alone or under-bench configuration

- Superior environmental control – through proprietary IR gas sensor, humidity and temperature control

- Widest temperature range – from -30°C to +200°C

- iMotion- ultra-fast controlled delivery of samples allows access times well below 10 seconds, even for samples sensitive to movement

- SafeErase automated decontamination without extreme heat and chemicals harmful to electronics*

- Contamination prevention – through LiCONiC exclusive alloy chamber*

- Water pan free – sterile humidity injection system eliminates need for water pan

- Unique orbital shaking – with amplitudes from 1 to 6mm*

- Ease of use – 8” touch screen – Graphical User Interface*

*

Even more flexibility is added by allowing to freely chose the type (please refer to Accessories table) and location (side, back or top) of the transfer-station.

Temperature controlled Small transfer gate guarantees extremely stable and reproducible environmental conditions for assays. Ultra-fast access times with optional iMotion Option allow controlled handling for very sensitive samples that require frequent loading and unloading by robotic platform.

Packages, Options and Accessories

Transfer Stations

Transfer Stations

Standard Station – fixed station outside the StoreX system which can be accessed by the StoreX handler as well as by any external robotic system. Main features include: alignment pins for realigning the microplates in both horizontal directions, it ensures easy adjustment of X / Y position, height and rotation of the transfer station plus easy access to the microplate for external grippers. Presence of a microplate checked by the plate sensor.

Shuttle Station – was designed for the elimination of an "inter transfer module", space constrains and complications of adding robotic arms for distances of 170-1000mm. The source plates can be transferred from one work area to another with precision accuracy. This delivery system can be used for multiple functions and work-station designs. The belt driven system ensures smooth transfer and accuracy of delivery.

Turn Station – mounted outside the StoreX system and rotates each microplate by 90 degrees before and after being accessed by the StoreX handler. Since the StoreX handler is transporting the microplate along its longer axis, this may be necessary if an external handling system requires the microplate in a different format. Rotation is controlled by the StoreX system, no additional external software required.

It has similar main features to Standard Station.

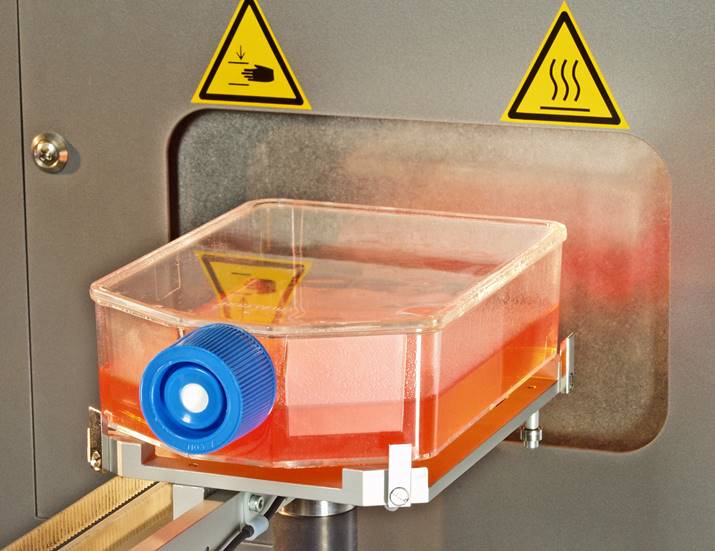

Flask Station – allows the transport of "robo-flasks" and 175ml T Flasks to your tissue culture workstation. It is the only design for this type of transfer and work on the market. Automating your tissue culture process is now possible.

Swap Station – mounted outside the StoreX system and consists of two transfer plates mounted on a swap drive rotating the transfer plates by 180 degrees.

The swap station acts as a plate buffer and as a plate extension shuttle. The distance of the actual transfer position is increased by 145mm. Two transfer plates act as a buffer for faster handling. Control of the Swap Station by the user system.

Lift Station – when stand-alone machines are placed under the table they can be provided with a lift station to transfer the plates to an external system.

The lift station is normally in the upper position, when handler loads or unloads a plate to the station the station goes to the load position.

Parallel Slide Station – The parallel slide station design allows a LiCONiC unit to be integrated with an external liquid handler without the need of an additional robot. With its precise stopping point it ensures that the devices need to be taught only once for accurate load and retrieval of the storage plates. The transfer nest is spring loaded to ensure the longevity of the liquid handling tips.

Slide Station – designed for the use of non-articulating robotic arms that need additional clearance from the storage units. With its precise stopping point it ensures these devices need to be taught only once for accurate load and retrieval of the storage plates.

Dual Station – designed for the use by non-articulating robotic arms that need additional clearance from the storage units. With its precise stopping point it ensures that the devices need to be taught only once for accurate load and retrieval of the storage plates. The dual slide station can be used to place an STR Line (Periscope) product between two existing instruments. Plates from an STR Unit can be fed to both the external instruments simultaneously.

Manual Station – is intended for manual single plate feeding operation. This special nest has extra wide alignment cones for safe and simple placement of a plate into the transfer station nest. It includes a plate detection sensor.

Universal Nest – for one plate and common interface between the LiCONiC instrument and the surrounding system. The transfer nest will accept SBS format plates. Specially developed alignment comes with optimized sliding properties will align plates for accurate transfer positioning. The transfer nest will correct for mis-alignment of over to +/- 2 mm.

Petri Dish Station – allows use of Petri dishes as well as most common storage plates.

iSeries Package – NEW!

iSeries Package – NEW!

Consists of GUI with touchscreen – displaying sample, climate, system and diagnostic data in plain graphic/text form and simplified data input, LED Rainbow Technology – instant display of system status, iMotion Option, Enhanced High Speed Barcode Reading Option, Liconel Option and SafeErase Decontamination Option.

n-Way Decontamination Package

n-Way Decontamination Package

Consists of steam injection that eliminates the need for water pan and causing no harm to the sensitive parts of the robotics, Liconel Option and Easy Clean Option – explained below.

Liconel Option

Liconel Option

Incubation chamber built of specially developed innovative alloy - Liconel - that acts as a toxic barrier for microbes while being absolutely harmless to the valuable substances stored and preventing corrosion. Liconel material technology combines the de-contaminating properties of copper ions with the advantage of extremely low aging effects as with stainless steel.

iMotion Option

iMotion

Intelligent technology that allows fast sample movement without the risk of losing the integrity of stored material due to high accelerations.

Easy Clean Option

Easy Clean Option

Allows to slide out the entire handling mechanism and base plate can be lifted to help to reach all internal parts of incubator chamber for easy manual decontamination.

SafeErase Decontamination Option

SafeErase Decontamination Option

Non heat based technology, safe for electronics and robotics.

CO

CO

As StoreX Incubators have to cope with frequent access they use a very advanced CO

N

N

As StoreX incubators have to cope with frequent access they use a high quality N

O

O

The sensors of oxygen measurement are based on the same principles as described above. The main difference is the measurement range of the sensor used in the CO

Barcode Reader Option

Barcode Reader Option

Can be installed on the Lift Assembly. It allows the reading of barcodes on plates stored in the stackers reading from the shorter side of plates facing outwards to the LiCotel Lift Assembly.

Docking Shuttle Option

Docking Shuttle Option

This feature allows multiple usage of one single port on the robotic integrated system. In addition it makes service and maintenance work easier by facilitating removal of the StoreX unit.

Orbital Shaker for 44 MTP size units

Orbital Shaker for 44 MTP size units

Orbital shaker with integrated auto-positioning for handler access. All functions required for access implemented autonomously. Driver compatible with non-shaker units, no special commands required for plate handling. All sub functions autonomously implemented. Available in 1/3/6 mm amplitudes with relative maximum RPM of 1200/600/400.

Linear Shaker for 110, 220 and 240 MTP size units

Linear Shaker for 110, 220 and 240 MTP size units

By accelerating and decelerating the carousel movement, a linear shaking function can be integrated in our carousel based units. Via software setpoints the amplitude and the speed can be adjusted.

Casettes

Casettes

All members of the StoreX series store the plates in cassettes that can easily be handled through the big user door by the operator. Cassettes are available for various plate dimensions. Even customized sizes are available at only slightly extra cost. All-metal Stainless Steel cassettes are also available. The number of levels within the cassette depends on the type of microplate.

- Specialized solid wall construction enabling superior sample integrity and reduced edge effect

- stainless steel

- can be taken out of the system for loading, unloading or cleaning

- can be exchanged between different systems

- storage of microtiter plates with lids possible

- Main features:

(Link do PDF) – Casettes

Modular Cascading System Option for STX1000

Modular Cascading System Option for STX1000

With this option system can satisfy growing library need. The cascading approach allows to start automation at minimum upfront investment while leaving ways for later expansion.

It gives maximum flexibility for integration. Interface ports are compatible to the STX Series instruments therefore giving access to the world's largest selection of transfer stations and other accessories. Collection can grow to the left or to the right and even addition of an extra robotic access port is possible. Access time on remote plates on a 2 stage system are below 90 seconds. Average pick and place times are 6 to 7 seconds.

Integration of LiCONiC Cascading System System is easy. LiCONiC's new 3rd generation driver package does all background and hardware related work while providing professional looking GUI for end-user access and service support.

Standard Software Features

STX Driver Package

STX Driver Package

It enhances user interface by providing the market's most complete and most powerful functionality at minimum programming costs. It includes everything needed to build a sophisticated, yet simple, interface for any plate storage application. All operations use drag&drop technology. The command set has been optimized using 21 very powerful and straight forward commands.

- intuitive and friendly user interface

- drag & drop plate manipulation

- device communication tools

- climate managing tools

- operation schedule

- test and diagnostics module

- error recovery system

- security system

- events, message and errors logging system

- TCP/IP communication

- remote access capability

- easy client-software integration

- multi-clients device managing

- multi-device compatibility

- The package features:

STX Panel Package

STX Panel Package

It is a software package designed to control all types of StoreX incubators. It allows to perform:

- climate control, including climate logging and drawing of graphs

- plate handling operations

- incubator gate and carousel control

- StoreX production tests

- executing low-level direct commands

Utility Software Package

Utility Software Package

Allows direct entering of commands (ASCII characters) and sending them to the Handling Controller. The commands can be entered as capital letters or prompt entries. It also allows usage of marcos – complete, preprogrammed command sequences.

There are few ready made programs being a part of the package: program to measure positioning times of the carrousel, program for positioning the carrousel randomly without gate movements, program for positioning the carrousel randomly including gate movements and program for positioning the carrousel randomly including combined positioning-gate movements commands.

UTX Active Control Package

UTX Active Control Package

Designed to ease the process PC to StoreX communication using USB or Serial COM ports. Without it users need to use Win32 API and USB Human Interface Devices API to communicate with the devices.

LiCONiC‘s proprietary technology delivers a robust system for frequent access and optimum environmental control using a variety of labware. Microtiter plates, deep well plates, culture flasks, petri dish and bioreactor tube options can all be accommodated as part of a standard solution range. All members of STR line can be equipped with various types of packages, options and a wide selection of useful accessories. For details please refer to Packages, Options and Accessories section of the web page and relevant flyer.

LiCONiC R&D succeeded in carefully embedding the new features in the existing well proven technology, without compromising its renowned reliability, thus ensuring an extremely high quality implementation. The StoreX iSeries greatly enhances LiCONiC’s products and provides the users with greater overall performance and stability which results in superior assay performance.